The Nova Scotia agricultural industry is committed to taking steps towards reducing its environmental footprint while striving to produce high quality food for consumers. A recent example of a new environmental initiative partnered a Nova Scotia dairy farmer with a local non-profit organization to test an innovative system for treating agricultural runoff, a common problem on farms. Agricultural runoff can contain nutrients, including nitrogen, which can have a negative impact on natural aquatic environments if left untreated. Several best management practices and technologies are currently in use on Nova Scotia farms to prevent and treat run-off including 4R nutrient management planning, engineered treatment wetlands and other farm-yard run-off flow controls.

This project was led by the Clean Foundation (Clean), a non-profit that helps communities make real progress toward a cleaner future by taking on climate change challenges. Funding was provided by Environment and Climate Change Canada with additional support from the Nova Scotia Federation of Agriculture. Rod Kennedy, a dairy farm owner in Antigonish living near a saltmarsh, provided his property as a test site. Rod’s family has farmed at this location for 3 generations starting in the 1930’s. He cares about the saltmarsh ecosystem and was excited to participate in this project.

What are the impacts of nitrogen runoff?

Nitrogen is an essential plant nutrient and it is added to agricultural soils as manures, composts and fertilizers. When nitrogen, in the form of nitrates, enters aquatic ecosystems, it can lead to the excess growth of algae which can ultimately lead to reduced sunlight for other aquatic plants, lower oxygen levels for fish and other aquatic organisms, and can produce detrimental toxic compounds.

A ‘do-it-yourself’ nitrogen treatment system

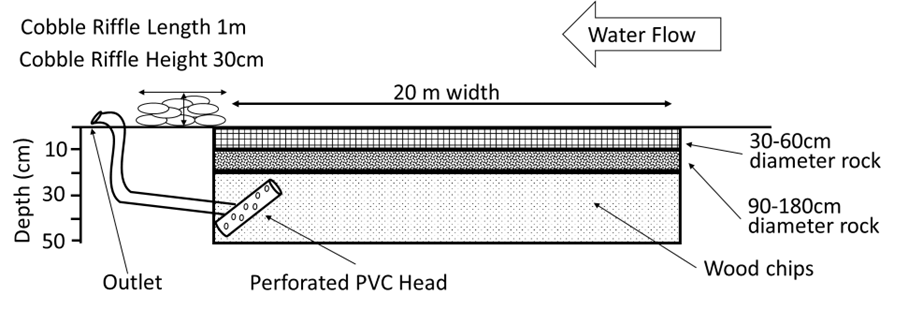

Clean recommended Rod construct a quick-to-install, cost-effective water treatment system known as a woodchip bioreactor. The reactor is essentially a trench filled with woodchips through which runoff water can flow. The woodchips provide a high surface area medium and a source of energy for beneficial bacteria to colonize. These bacteria can transform nitrate-nitrogen, into harmless atmospheric-nitrogen using a process known as denitrification. On average, woodchips can denitrify water from agricultural runoff at a rate of 3.8 milligrams per liter (Robertson & Merkley, 2009). Bioreactors work best in summer temperatures when microorganisms are more active. Research has shown however, that bioreactors in ice-covered streams are still able to remove nitrate and allow water flow, making them a suitable solution for Canadian farm owners (Robertson & Merkley, 2009). The simple design of this system is outlined in detail below.

Four quick steps to install a bioreactor under $10,000

Rod followed these four simple steps, to install his bioreactor in one day:

Step one: Dig a Trench

With the help of Baxter Excavation, a 20 m x 2 m x 50 m deep trench was excavated in a streambed near the drainage ditch on Rod’s property.

Tip: Communication with permitting regulators is key

For Rod’s drainage ditch, a permit was required, which adds about 90 days to the planning phase. His ditch had been there for over 50 years and is now considered a watercourse. Reach out to your local inspector with the Department of Environment before you begin, regularly communicating updates with your inspector through the process.

Step two: Add an outflow point

Rod added an outflow point to allow the filtered water to exit the bioreactor. To allow outflow, a 10 cm perforated PVC pipe was placed at the bottom of the trench and connected to a drainage pipe that extends above ground (figure 2).

Step three: Fill with woodchips

Next, woodchips were added to the trench in a bed measuring 20 m x 2 m x 0.3 m (figure 3).

Step four: Top with rocks and add a pebble pile

To slow down the flow of water and allow it to efficiently enter the bioreactor, the woodchips were topped with a 10 cm deep bed of large-sized (90-180 cm diameter) rocks (figure 4).

Then, a 10 cm bed of medium-sized (30-60 cm diameter) rocks was placed on top of the large rocks (figure 5).

Finally, a pebble pile measuring 1 m X 2 m X 0.3 m was placed at the end of the reactor, to further contain the flow of runoff (figure 6).

With the project now complete, water from Rod’s farm will now flow through the bioreactor. Continued monitoring of this site will be valuable to measure how much nitrogen is in the water before and after treatment in the bioreactor. It has been 5 months since the installation, and to date, both Rod and Clean are happy with the success of the project. They hope more Nova Scotian farm owners will consider a woodchip bioreactor as a possible solution for their water quality needs.

References